Rework Processing with TRP technology

The basic principles of TRP technology

The automatic process combines rubber processing with proven methods such as cracking, homogenization and discharge.

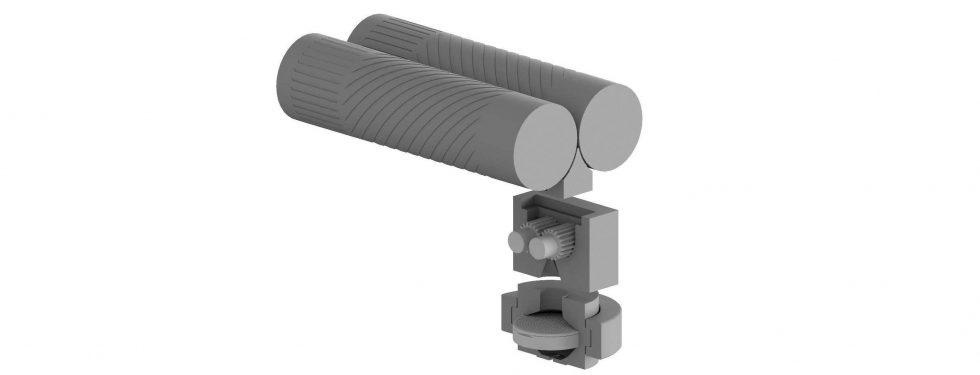

This compact system consists of 3 zones located along the length of the roll:

In the feeding zone materials of various types and shapes, such as sheets, slabs or shaped profiles are dropped into a hopper by a conveyor. In the homogenization zone a mechanical transformation takes place. In the discharge zone the material is automatically formed following the proven roll-ex® TRF principle.

This results in a reproducible and continuous process which is fully automated and encapsulated. Depending on the application, the TRP is energy-efficient in comparison to existing processes and requires a smaller footprint.