Silicone Compounding

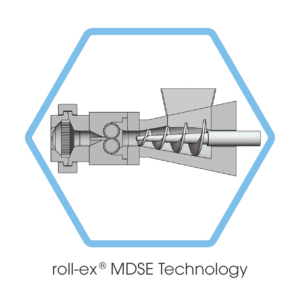

roll-ex® MDSE: Integrated solution for batch-mixing and discharging based on the conical twin screw extruder

PROCESS APPLICATION

The mixing of silicone rubber and elastomers of low viscosity in batch operation and then the forming of blocks, strips or plates in one operation. Alternatively, the material can also be transferred directly to a connected downstream unit – for example to a roll-ex® gear pump or a screw extruder.

The MDSE is based on the principle of the conical twin screw extruder. Two conical screws counter rotate and intermesh. The material to be mixed is fed into the hopper, passes through the pressure area into the mixing zone and then returns to the infeed hopper. This process can be repeated according to variable parameters until a homogenous compound is formed.