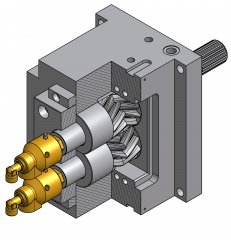

Gear Pump

UTH – Pioneer in gear pump technology

Rubber processing presents major challenges to rubber and tire manufacturers on a daily basis. What is required is the highest level of product quality while at the same time increasing economic efficiency. The roll-ex® extrusion system developed by UTH provides an innovative solution for particularly gentle processing and has thus become the worldwide benchmark for the fine mesh straining of rubber compounds.

The secret is in the strictly volumetric conveying principle of our gear pump. This creates a uniform and synchronous flow of material – irrespective of the counter-pressure.

Roll-ex® gear pump technology:

- Patented design of elementary components

- Modular set-up for individual solutions

- Easy and quick to clean

- High pressure up to 800 (500) bar

- Temperatur remains exensively constant

- Low energy requirement (70% energy savings)

UTH is a pioneer in the field of gear pump technology for fine mesh strainers and precise extrusion. Due to the modular system different feeding devices and extrusion or strainer heads can be combined with the gear pump according to the application. This enables customized solutions.