Quality improvement of tire compounds by efficient fine mesh straining-technology

New, innovative solutions for the processing of rubber compounds at the Tire Technology Expo 2018 in Hannover from 20 – 22 February.

UTH GmbH from Fulda/Germany will exhibit its extended range of pro-ducts at stand no. 4012. The company’s core competencies covering both roll-ex® fine mesh straining systems and roll-ex® gear pump technology. Based on these systems, tire manufactures around the globe are simoultanous able to face rubber processing challenges and meeting highest quality targets along with operating cost efficiency.

UTH has gained profinciency in perfecting the manufacturing of specialized products supplied to different areas of the tire manufacturing industry. Typical applications can be found within the mixing lines for final compounds and master batches, in complete offline straining cells, in profile extrusion lines or in the reworking of tire compounds. “It has been proven, that the quality of rubber compounds can be improved significantly by fine mesh straining”, clarifies Peter J. Uth (Managing Director, UTH GmbH).

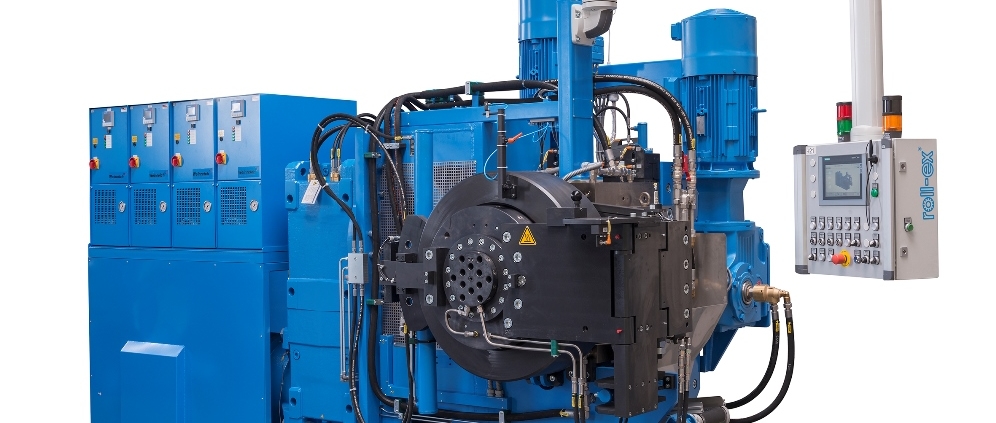

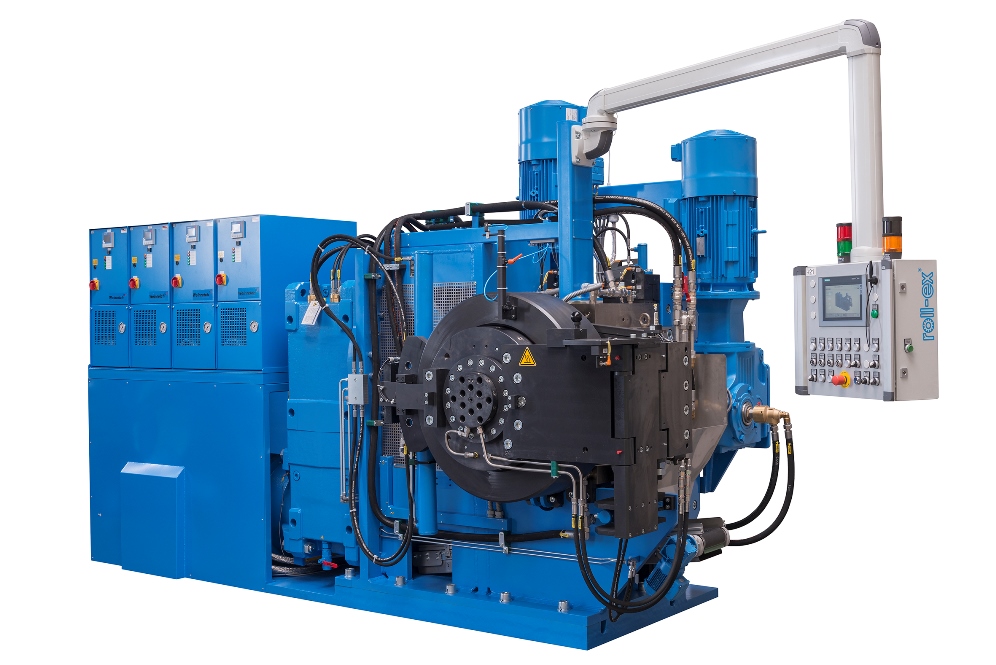

Accordingly, UTH has made progress in perfecting the manufacturing of tyre, rubber and silicone products. The roll-ex® gear extruder systems from UTH have set the benchmark worldwide for fine-mesh straining of rubber compounds. With throughputs up to 10000 kg/h the Gear Pump Extruders are a particulary good choice for the operation in mixing-lines of the tire industry. Using either the compact two-roll feeder (TRF) or a conical twin screw feeder (DSE), the modular design of the roll-ex® system enables the integration of the strainer in each specific line design.

Because of the flexible and compact design, a seemless integration into existing lines is also possible. The high level of automation, as well as the very gentle processing of compounds in the gear extruder, keep the impact on the existing processes to a minimum. The supply of intelligent up- and downstream equipment to enable a seemless integration of the strainer in even the largest mixing lines completes the portfolio of UTH. Where necessary, dedicated individual solutions are developed together with the customer. In addition, UTH offers a wide range of accessories and provides customers with a global service and sales network.

Further information on the particular benefits and possible applications of roll-ex® technology ist available at UTH, stand no. 4012.

roll-ex® 600 TRF with a throughput of 6.000 kg/h