New solutions for the processing of rubber compounds at the DKT / IRC in Nuremberg

On stand no. 12-129, UTH GmbH from Fulda, Germany presents its again expanded product range, in both the areas of roll-ex® fine mesh straining and roll-ex® gear pump technology. The outstanding highlight is the new offline solution for the straining of rubber compounds, the roll-ex® straining cell.

Rubber processing presents enormous challenges day in day out to rubber and tyre manufacturers. The demand is for the highest level of product quality while simultaneously increasing operating efficiency. Accordingly, with the straining cell UTH GmbH has made fresh progress in perfecting the manufacturing of tyre, rubber and silicone products.

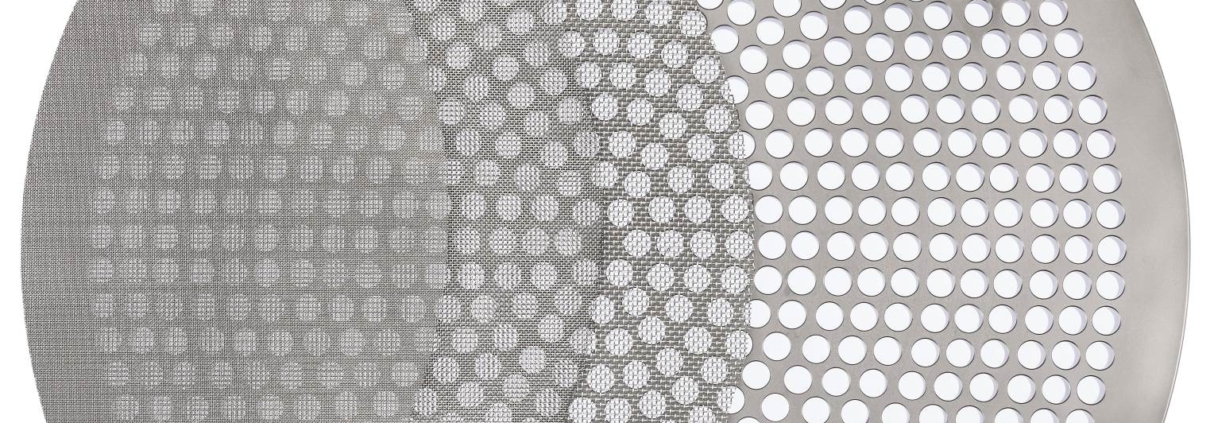

The straining cell developed by UTH is a fully automated solution for the fine mesh straining of rubber compounds (offline), consisting of strainer, strip cooler and stacking and packing device. In the process, the modular roll-ex® gear extruder can be combined with both a two-roll feeder (TRF) and a screw feeder (SF).

After the straining process, the material is intensively and uniformly cooled in a high-performance drum cooler. The cooling technology, which is particularly gentle on the material, prevents deformation and anti-adhesive concentrations on the strips. The clean material is then packed in an extremely space-saving manner by means of an ingenious packing and stacking device. The individual units of the straining cell can be arranged in a way that is flexible and very compact, which also allows the production of customised solutions.

As a fine mesh straining and precision extrusion specialist, UTH GmbH uses exhibits to advise on the specific advantages and possible applications of roll-ex® technology on stand no. 12-129.