UTH presents a new dimension of fine mesh straining in the mixing line at the DKT in Nuremberg

New solutions for the gentle and clean processing of rubber compounds at the German Rubber Conference DKT 2018, taking place in Nuremberg from July 02 to 05, 2018.

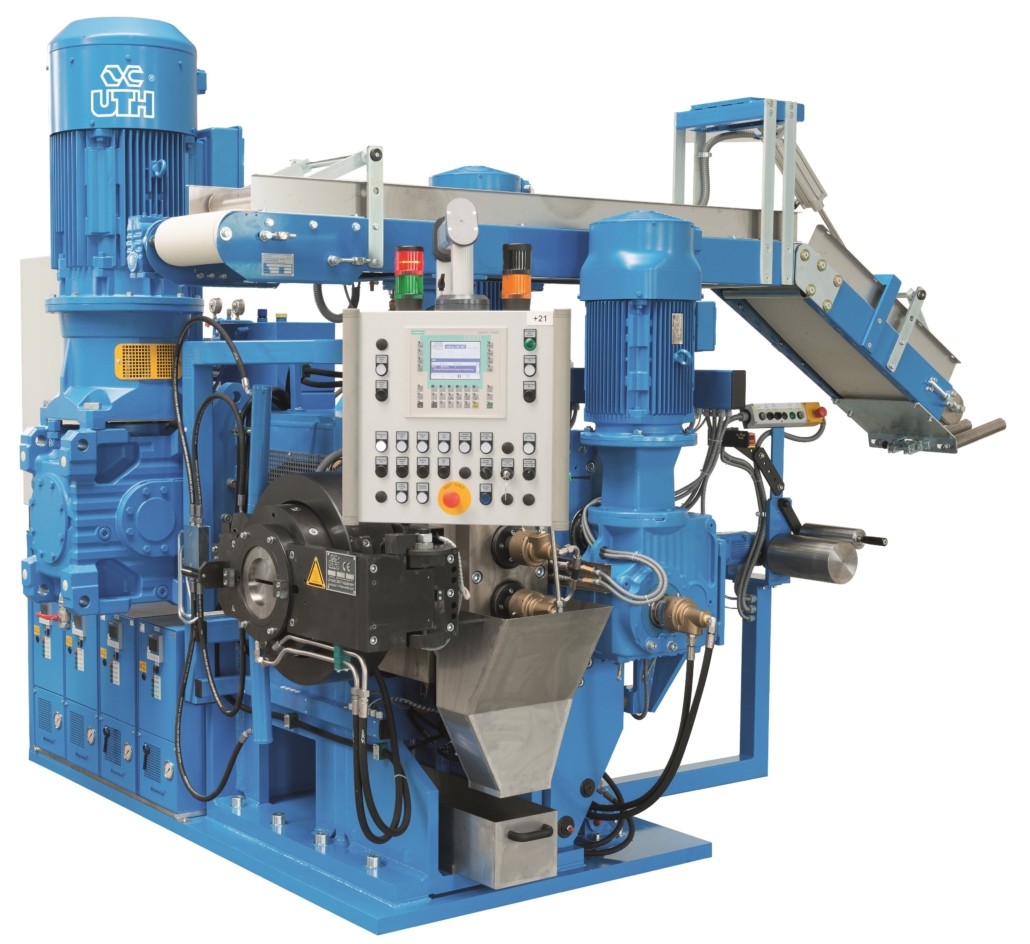

At stand no. 139, hall 12, UTH GmbH from Fulda/Germany presents its latest product range, in both the areas of roll-ex® fine mesh straining and roll-ex® gear pump technology. The outstanding focus is a highly cost-effective and innovative solution for the fine mesh straining of final compounds in the mixing line: the roll-ex® 220 TRF.

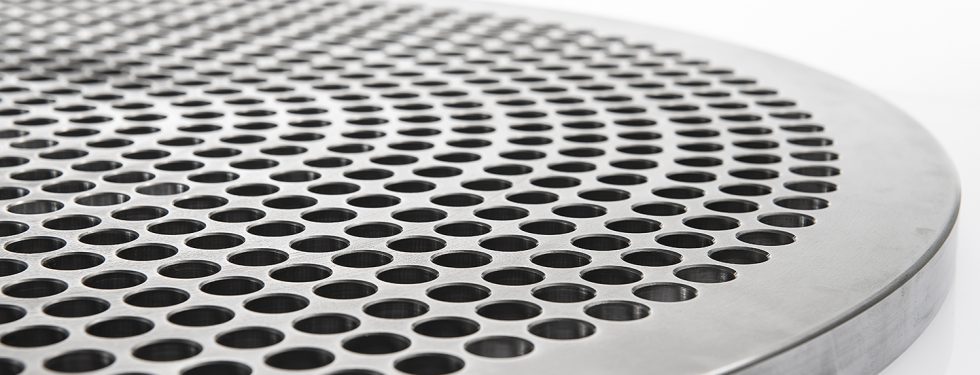

Rubber processing presents enormous challenges day in day out to rubber and tyre manufacturers. The demand is for the highest level of product quality while simultaneously increasing operating efficiency. Accordingly, with the roll-ex® 220 model UTH offers an economical solution for the manufacturing of tyre, rubber and silicone products. The roll-ex® 220 TRF is designed for throughput rates of up to 2,500 kg/h and guarantees a high productivity.

It is advantageous to use roll-ex® gear extruders (even with frequent compound changes or the usage of coloured materials), since they can be cleaned quickly and thoroughly on account of their patented design. The modular roll-ex® system can be combined with a two-roll feeder (TRF), a screw feeder, or a conical twin-screw extruder. Throughput rates of up to 10,000 kg/h are possible. The roll-ex® extrusion system developed by UTH has become a benchmark for fine mesh straining of rubber compounds worldwide.

Precise extrusion is another primary application of roll-ex® gear extruders and gear pumps, where high operating pressures (up to 800 bars) can be applied. UTH can offer, among other things, system solutions (including the supply of complete lines) for the manufacture of rubber-coated wire, yarn or fibre components.

UTH will be providing further information (on the basis of an exhibit) on the particular benefits and possible applications of roll-ex® technology at stand no. 139 or in the web: uth-gmbh.com

roll-ex® 220 TRF; throughput rates of up to 2500 kg/h