UTH Showcases Next-Generation Rubber and Silicone Processing Technologies at Global Polymer Summit 2025

FORT MILL, SOUTH CAROLINA — UTH, a global leader in fine mesh straining, gear pump technology, and advanced mixing solutions for rubber, silicone, and polymer processing, will present its latest innovations at the Global Polymer Summit 2025, held September 8–11 at the Huntington Convention Center in Cleveland, Ohio.

Celebrating 40 years of engineering excellence in 2025, UTH continues to set new industry benchmarks in demanding production environments worldwide where precision, efficiency, and reliability are essential.

Visit the UTH North America Inc. Team at booth #1501 to explore a wide array of advanced processing solutions, including the company’s modular roll-ex® Gear Pump Technology—renowned for its gentle, precise, and energy-efficient material handling.

New technologies featured will include next-generation machines:

- New Two-Roll Feeder (TRF) Dual-Drive system, delivering lower maintenance costs, longer service life, and reduced wear

- The Two-Roll Plasticizer (TRP) for energy-efficient rework processing and continuous milling of rubber and silicone

- The highly accurate Polymer Dosing System (PDSE), engineered for the precise dosing of high-viscosity materials

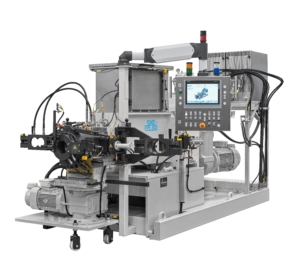

- Mixing Conical Twin-Screw Extruder (MDSE) for next-level silicone compounding solutions that ensure superior material homogeneity and surface quality for high-performance applications

“Today’s market demands solutions that combine precision, performance, and cost-efficiency,” said Bill Bisson, General Manager Sales & Services at UTH North America Inc. “With over four decades of technical expertise, we help our customers optimize production across extrusion, straining, recycling, and silicone processing.”

Thanks to the modular roll-ex® system and its compatibility with innovative feeding units, UTH’s solutions can be flexibly configured for a wide range of applications. These include technologies such as the Two-Roll Feeder (TRF) for fine mesh in-line straining applications, the Single-Screw Feeder (SF) for off-line straining, precise continuous extrusions and highly accurate continuous preforms, and the Conical Twin-Screw Extruder (DSE) for batch-mixing and discharging in silicone applications (MDSE) as well as precise dosing of viscous to highly viscous polymers (PDSE).

Attendees are also invited to join the technical presentation by Julia Uth, President of UTH North America Inc., on September 9 at 2:00 PM. Her session will focus on Automated Processing Technologies for Silicone Rubber Compounds.

More information can be found on www.uth-northamerica.com.

The MDSE, conical twin-screw extruder with feed hopper for silicone compounding application (optional: with integrated roll-ex® gear pump)